New things

New things

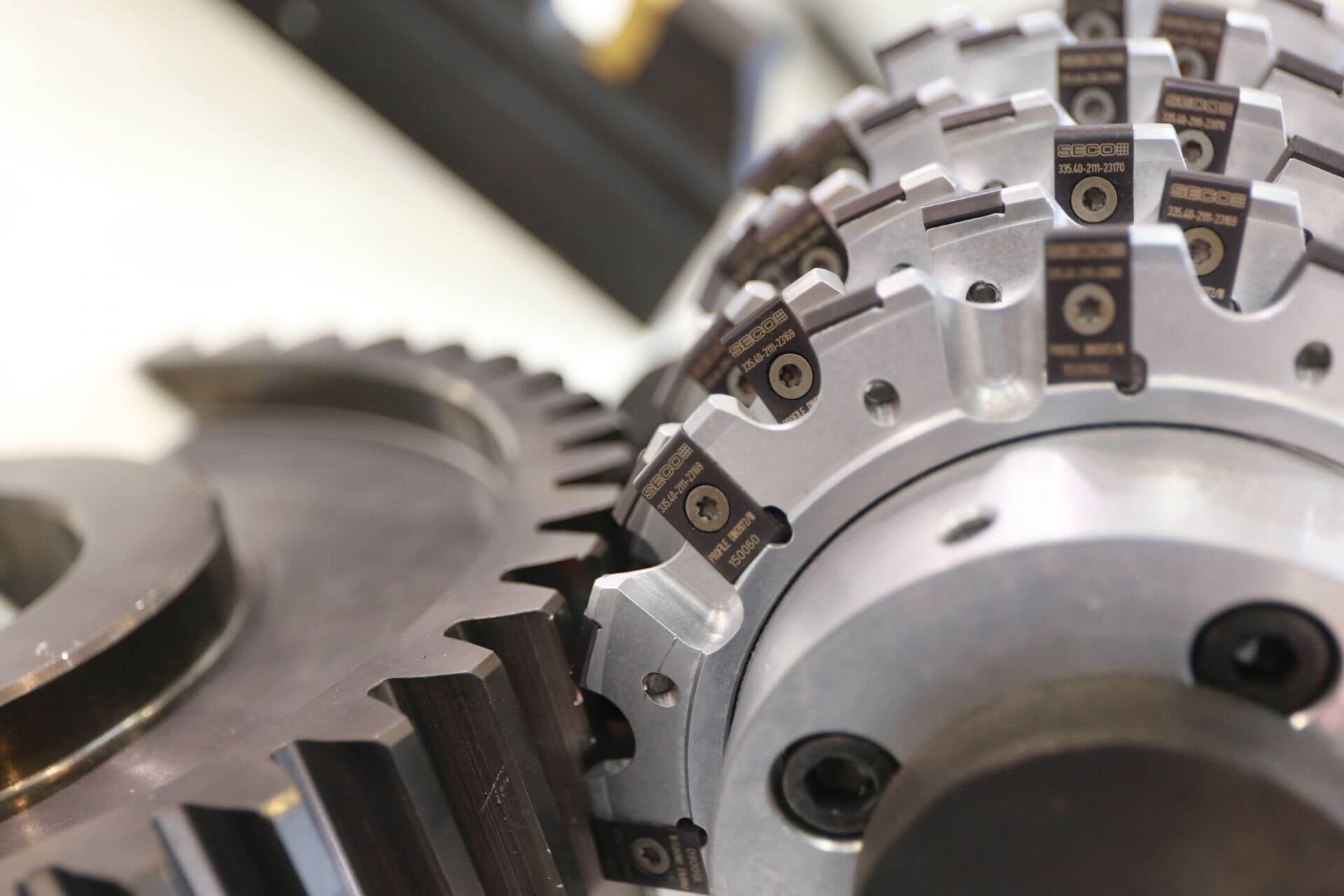

Special machine for groove processing

In order to meet the needs of the market and the manufacturing industry, a certain optical ruler brand has continuously innovated and developed high-efficiency and high-flexibility customized machine models of bed-type milling machines to meet different processing needs, including the innovative development of customized groove processing special The machine can be used for precision milling of straight grooves, oblique grooves and spiral oblique grooves, including gear hobbing tool grooves and spiral grooves, woodworking machinery tools, plastic pellet mill cutters, nut milling grooves, and teeth The production of plate molds can also be used with any brand CNC controller and the fourth axis for more efficient and precise spiral oblique groove milling and grinding operations.

https://www.zinde.com.tw/Product advantages

According to the major optical ruler, it can be matched with the universal head model, and its spindle head rotation angle can be used for milling production of broach tools and complex woodworking tools. If it is equipped with a CNC controller, it can be used for precision production of bevel gears. Horizontal groove grinding machine can be equipped with grinding spindle head rotated 90 degrees to perform oblique angle grinding in the front and rear Y-axis direction. It can do precision grinding for broach tools, etc. If it is equipped with CNC controller and optical ruler feedback signal detection , Can obtain higher precision accuracy.

客製化設計

In recent years, in response to the special processing needs of many customers, this large optical ruler has specially produced machinery specially used in the production of high-precision screw and dental plate molds. It can meet the production needs of major dental plate manufacturers and has achieved excellent results. The repurchase rate and word of mouth are positive. In addition, the optical ruler specifications can also be customized.